a. Thermo analytical facility for basic studies (TGA-DSC)

b. Drop Tube Furnace (DTF)

c. Fuel Evaluation Test Facility (FETF)

ii) Renewable Energy &BioTechnologySection

| Sl. No. | A brief description of Facilities/ Equipment/Tools/software with photos |

|---|---|

| Major Facilities | |

| 1 |

Phase Contrast Microscope: Facility created and used for microbial identification

Centrifuge: Facility used for value added products extraction from algae

Algal Culture Lab Facilities for culturing micro algae

Fermenter: Facility for Biofuel production

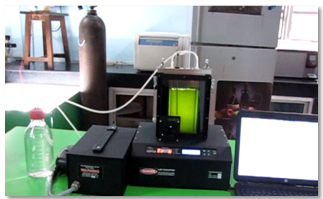

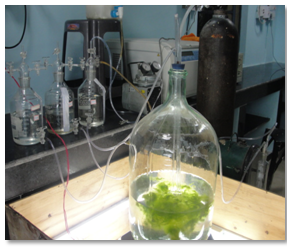

Bio methane reactor:Facility for methane production  Photo Bioreactor: Facility for pilot scale culture of micro algae  Bio-methane Reactor: Facility for Moveable bio-methane reactor for rural energy demand  Flat panel photobioreactor: For algal culture  Lab scale photobioreactor: For algae culture  Cylindrical photo-bioreactor: For CO2 capture studies  Hybrid photobioreactor: For algae culture  Renewable Energy and Biotechnology Research Highlights |

| 2 |

Thermogravimetric Analyser (TGA-DSC, Model STA 449F3, NEZSCH, Germany): Used to study combustion behavior of coal, coal blends and coal biomass blends in lab scale.

DTF (Drop Tube Furnace, 1-3kg/hr): Used to study combustion behavior of coal, coal blends and coal biomass blends in bench scale.

FETF (Fuel Evaluation Test Facility, 25-70kg/hr): To study combustion behavior of coal, coal blends in pilot scale and study oxy-fuel combustion. |

| Sl.No. | Project | Sponsor |

| Combustion Science and Technology Section | ||

| 1 | Co-combustion under Clean Coal Technology (TapCoal) CSIR-12th FYP project | Council of Scientific and Industrial Research (CSIR) |

| 2 | Oxy-fuel Combustion under Clean Coal Technology (TapCoal) CSIR-12th FYP project | CSIR |

| 3 | Looping Combustion under Clean Coal Technology (TapCoal) CSIR-12th FYP project | CSIR |

| 4 | Advanced ceramic materials and components for energy and structural application (CERMESA) CSIR-12th FYP project | CSIR |

| 5 | Investigation on the combustion behavior of coals/coal blends of different types and origin to assess their suitability for pulverized coal injection in Blast Furnace | TATA STEEL, Jamshedpur |

| 6 | Energy Sector Inventory: [Biennial Update Report and Third National Communication]: Preparation of National GHG emission Inventory for Energy and Manufacturing Industries for different years | United Nations Development Programme (UNDP), New Delhi |

| 7 | Normative coal requirement for different industries | Coal India Limited,Kolkata |

| 8 | Utilization of Sludge by blending with coal | CSIR-NEERI, Nagpur |

| Coal to Chemicals Section | ||

| 9 | Study the conversion of pyridinebased chemicals to pharmaceutically important molecules: | CSIR-CIMFR, In house |

| 10 | Pilot scale demonstration of “silica composite “Si-Bps- HAs” (Silica-Botanical pesticides-Humic acid) from coal ash/biomass ash/biogenic silica richresources as bio-pesticide foragricultural/store grain pests control | CSIR |

| 11 | Pilot scale demonstration of coal mine water usage for commercial algal production for food – fertilizer in hybrid photo-bioreactor for combating malnutrition | CSIR |

| 12 | Bio-processing of coal industrial effluent and coal fines recovery using aquatic plants and phototrophs | Central Power Research Institute (CPRI), Bangalore |

| 13 | Bio-methanationof coal rejects/low grade coal andbiomass -Demonstration Modelat villageGaurigram, Chandankiyari, Dhanbad | CSIR |

| 14 | TAP COAL: CO2 mitigation, bio-H2 production & recovery of novel bio-products from coal combustion flue gas using micro algae | CSIR |

| 15 | CO2 capture through microbial route in pilot scale GAIL;Pata | GAIL, Pata |

| 16 | Study of CO2 signaling among single cell and filamentous microalgae under elevated CO2 and screening of high value products for commercial application | CSIR-CIMFR, In house |

| 17 | Process for synthesis of PHA(polyhydroxyalkanoic acids)- A biodegradable plastics from bio-depolymerized lower rank coal | CSIR-CIMFR, In house |

| 18 | Screening andcharacterization of extremophilesmethanogenicbacterial consortiumin coal bed methane reservoir and study on its application for recovery ofmethane | CSIR-CIMFR, In house |

| 19 | Art & Craft from coal- Skill development for rural women | CSIR-CIMFR, In house |

| 20 | Renewable and bio-degradable novel fabrics and pigments from CO2 capture algal biomass for commercial application | CSIR-CIMFR, In house |

To provide basic R&D and industry support in the area of coal combustion, clean coaltechnologies, coal derived chemicals, clean fuel solution andbio-processes.