| Sl. No. | A brief description of Facilities/ Equipment/Tools/software with photos |

|---|---|

| Major Facilities | |

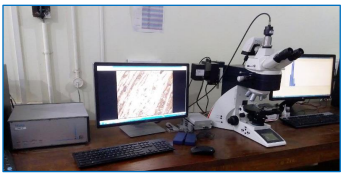

| 1 | Determination of In-situ gas content of coal/shale samples: In-situ gas content of coal/shale core samples is determined by Direct Method, the method is consisted of three stages measurement process. In this method, coal/shale core samples are collected in a desorption canister, a cylindrical type of vessel of different diameter, to measure the desorbed gas volume at ambient pressure and temperature. .png) Gas Chromatograph: The Gas chromatograph is used to analyze desorbed gas to check quality for the assessment of coalbed methane/ shale gas resource potential for commercial utilization. It is also used to determine methane content at ppm level used to estimate fugitive emission of GHG from coal mining activities and other sources.  High Pressure Adsorption Isotherm (HP AI) Experimental Setup: A High Pressure Adsorption Isotherm construction facility was designed and developed at CSIR-CIMFR, Dhanbad through the project funded by SERB, DST vide grant no. SR/S4/ES- 591/2011 to investigate the dsorption characteristics of coal/shale at replicated in situ conditions.  Elemental Analyzer: A facility for the determination of elemental C, H, N, S and O (by difference) composition of coal sample has been established. Elemental analysis is an essential requirement for research on coal genesis and various coal conversion processes. The elemental composition is essential to decide the rate of injection, type of oxidant, amount of steam to be used to get the desired quality of syngas.  Leica make DM 4500P microscope: Coal is a heterogeneous mixture of organic and inorganic, and it is from the organic component that syngas is generated during gasification. The inorganic component has a significant impact on gasifier performance. Hence petrographic study of coals is essential. Maceral composition and reflectance analyses are carried out following the ISO/IS standards using the Leica make DM 4500P microscope. The microscope is equipped with MSP 200 attachment for reflectance measurement, fluorescence attachment for identification of liptinites, Digital Colour CCD Camera with built-in Peltier cooling system for image capturing and Leica Application Suite software for image analyses. Both mineral phases and organic components can be studied using this polarized microscope  Surface Area Analyzer: A facility has been added for Low pressure sorption isotherm system for surface area, pore size and pore volume of shale/coal/rock samples.  |