I-10 |

Intelligent dry fog dust suppression system |

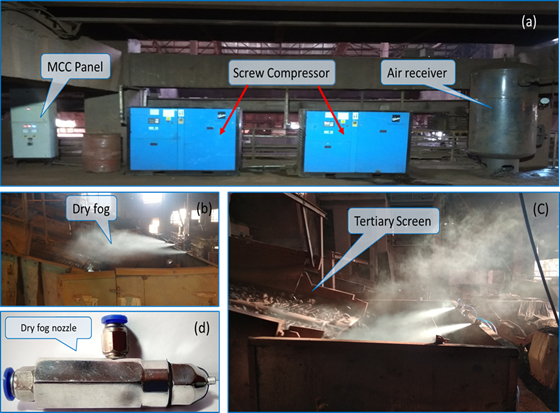

An automated and smart dry fog dust suppression system has been developed for efficiently controlling fugitive dust emission from mining and industrial operations. The system consists of hybrid nozzles, sensors, actuators, controllers, screw compressors, air receiver, pumps, motors, and water arrangement with filtration facility. The system automatically starts operation only when the plant is in operation and effectively controls dust emission at source. The system does not affect the material handling process as it adds moisture ˂0.1% of material weight. Major features of the system are as follows:

● Compressed air and water pass through atomization nozzles to form fine droplets (10 to 50 �m with a mean of 20 �m);

● Fine water droplets agglomerate with fugitive dust particles of sub-micron range and settle down;

● The process adds only around 0.1% moisture on the processed mineral; and

● Total operation is automatic using programmable logic controller and sensors (under belt sensor, proximity sensor, dust measurement sensor, water level, etc.).

Dry fog dust suppression system, (a) Air compressor system installed at mine site, b) Dry fog generation, (c) Dust suppression system operation at tertiary screen, and (d) Dry fog nozzle.

National/International Status

Diverse techniques are being used in mining areas to control dust. Unlike conventional water spraying systems, the dry fog system or mist fog system uses the dry fog technique or mist fog technique for dust suppression. The dust particles and micron size fog droplets collide and adhere to each other, and their mass increase. After several such collisions, the mass becomes heavy, which causes dust settlement. An automated and efficient dust suppression system has been developed that combines hybrid, ultrasonic nozzles and atomizing nozzle to spray dry fog through atomization of water drops in the range of sub-micron metre size (1�20 �m size) for accurate agglomeration with dust particles (PM2.5 and PM10).

Field Implementation

The system has been installed in crushing and screening plant of Donimalai Iron Ore Mine of National Mineral Development Corporation (NMDC) Limited, Karnataka.

Patent/Technology Transfer/Commercialization details:

● Patent: �Intelligent dust suppression system for mining applications�, Patent Filing Application No. 201811014398, dated 16.04.2018

● Technology Transfer: The technology has been transferred to M/s Control Systems and Solutions, Kolkata for commercialization of the system.

Techno-economics

The system consumes low power, automatic, easy to maintain, and capable of handling dust problems in the closed environment of crushing and screening plants. These properties make the system techno-economically feasible for installation in mineral processing plants and mining areas.

Industrial Benefits

The system reduces the breakdown and maintenance cost of mining equipment, thereby decreasing overall operating costs. Further, the system minimizes mine workers' health problems, like silicosis and several other occupational diseases.

Stakeholders/Clientele

Mining industries, cement industries, processing plants, thermal power plants, mechanical and electronic system manufacturing industries, etc.

Future Plan

The scope for future innovation are addition of an automatic alarm system for nozzle maintenance, and the application of artificial intelligence for deciding nozzle numbers based on the dust concentration in the air, production quantity, wind speed, and belt conveyor speed.

I-11 |

Mine transport surveillance system |

Mine transport surveillance system (MTSS) has been developed for controlling unauthorized transportation of mineral from mines, accurate and full-proof weighing by proper positioning of trucks and controlling overloading, periphery surveillance of mine boundary, on-line monitoring and surveillance of mining activities as well as improving safety, production and productivity of opencast mines. MTSS consists of different modules for different purposes, namely:

● Weighbridge automation for fast, accurate and automated weighing process;

● Centralized billing and software solution for secure and transparent on-line dispatch and production monitoring;

● Long range proximity warning device for safety of heavy earth moving machinery;

● Global positioning system (GPS) and radio frequency identification (RFID)-based vehicle tracking and production monitoring module for keeping continuous watch on the vehicles on geo-fenced transportation routes, and monitoring of production as well as providing advice on optimum use of shovels and dumper;

● Periphery surveillance using virtual fencing for detecting intrusion of vehicles with the intention of illegal transportation of mineral through unauthorized routes as well as identifying human intrusion into an industrial area; and

● In-motion weighbridge for weighing of mineral produces from mine.

|

|

|

|

|

Weighbridge automation |

Mine periphery surveillance |

Long range proximity devices |

|

Mine transport surveillance system |

||

Field Implementation

The system has been installed at Kumaraswamy Iron Ore Mine, Donimalai Iron Ore Mine and Pellet Plant of NMDC Limited. The system has been operating successfully during last 4 years at the site. Field trial of the first system was also carried out by deploying the total system at Tirap opencast coal mine of North Eastern Coalfields of Coal India Limited. The RFID devices have been tested by SAMEER, Kolkata and approved by Wireless Planning Coordination.

Patent/Technology Transfer/Commercialization details

● Patent: �Mine transport surveillance system�, Patent Application Filing No. 2107/DEL/2015, dated 13.07.2015.

● Technology Transfer: An agreement has been made with M/s Dadhwal Weighing Instruments, Dhanbad for implementation of the system in different mines.

Techno-economics

The system helps to check unauthorized entry of vehicle, mineral overloading and illicit mineral transportation in opencast mines. It facilitates an efficient dumper tracking and management system, effective visualization of transportation activities throughout the mine lease, optimum deployment of shovel-dumper combination for enhancement of production, efficient measurement of mineral weight using weighbridge automation, on-board weighbridge and in-motion truck weighing system, controlling illicit mineral transportation from mines, and optimization of transportation schedule depending on the operational constraints. These facilities make the system techno-economically feasible for installation in opencast mine.

Industrial Benefits

This would also help in checking unauthorized mineral transportation, vehicle overloading, controlling mineral stealing, improving productivity, saving of royalty by the government and safety in opencast mines.

Stakeholders/Clientele

Mining industries, cement industries, thermal power plants, electronics manufacturing industries, etc.

Future Plan

Interaction with the mining and other industries for its application, and further improvement of the device with the latest technique.

I-12 |

Vision enhancement system for foggy weather |

Vision enhancement system (VES) is an intelligent driver assistance technique for effective visualization of transportation path as well as loading/unloading areas during foggy weather with the help of thermal imaging cameras, high definition cameras, proximity radio detection and ranging (RADAR), rover/global navigation satellite system (GNSS), rugged� graphical processing unit (GPU), wireless devices, laser light, roadside edge detection arrangements (using flasher light and self-regulating heating cable), etc.

The system provides 180� panorama field of view through real-time video stitching and image processing, rear view, object detection through proximity radar and GNSS, real time location of the vehicles by GNSS modules, audio-visual alarm to driver on object detection, processed and integrated outputs displayed on a touch screen fitted on dashboard, and display screen logically splitted into 4 quadrants. The top half displays the output of integrated algorithms applied to internet protocol (IP)-based cameras, and the lower section is further divided into 3 windows for proximity radar view, GNSS-based navigation, and the road's rear-view to provide multi-stage maneuvering and safety. The drivers can select any particular window using a touch panel to display on the full screen, while the other windows continue to run in the background and pop-up an alert when necessary. A network switch is used for the terminal connection of all ethernet-based modules. Finally, a rugged GPU is used to process all the cameras, proximity radar, and GNSS information using advanced analytics and artificial intelligence (AI). The system uses advanced analytics, artificial intelligence and image processing techniques for real-time video processing, fleet management, object detection, proximity warning using RADAR and GNSS.

|

|

|

|

Fitting of various devices on dumper |

Integrated screen view in front of driver�s dashboard |

|

Vision enhancement devices |

|

National/International Status

No proper system is available for continuing opencast mining operation during dense foggy weather. The developed system provides multi-layered protection and visualization of mining operations using various techniques to enhance the operators' visibility. The system has backup security measures like proximity radar, anti-collision laser light, etc., apart from visibility enhancement algorithms. The developed image processing algorithm has significant advantage over the existing image dehazing technologies. The system reduces road accidents by reducing human error. It avoids accidents and collisions by offering technologies that warn the driver of oncoming obstacles.

Field Implementation

The system is being implemented at Bacheli Complex of Bailadila Iron Ore Mines of NMDC Limited in Dantewada district of Chhattisgarh state.

Patent/Technology Transfer/Commercialization details

● Patent: �Vision Improvement Device for Harsh Atmosphere caused by Temperature Attenuation (VIDHATA)�, Patent Filing Application No. 201811808681, dated o8.03.2018.

● Copyright: �Real-time image processing method and software�, Copyright Registration No. 015CR2020, dated 20.10.2020

● Copyright: �Method and software for real-time image stitching and object detection�, Copyright Registration No. SW-13959/2020, dated 09.12.2020.

● Technology Transfer: The patented technology has been transferred to M/s Dadhwal Weighing Instruments, Dhanbad for commercialization of the system.

Techno-economics

The integrated system with multistage safety features helps the mining machinery operators to see through fog and provides alerts in case of route deviation, obstruction and impending collision. These facilities make the system techno-economically feasible for installation in opencast mines.

Industrial Benefits

● The system helps in continuing opencast mining operation during foggy weather.

● The system improves safety and productivity in opencast mines.

Stakeholders/Clientele

Mining industries, electronics manufacturing industries, etc.

I-13 |

Digital mine system |

A digital mine system has been developed for monitoring and prediction of mine hazards to improve safety and productivity in underground mines. The integrated system includes different modules covering hardware and software for: (i) environment and gas monitoring, (ii) strata monitoring, (iii) fire and explosivity status monitoring, (iv) miners tracking and voice communication, (v) water level monitoring and stowing practices, (vi) on-line production and dispatch monitoring, (vii) store inventory management, (viii) personnel management, (ix) on-line form submissions and e-governance, (x) training module, etc. The system uses internet of things (IoT)-enabled sensors and control units, flameproof and ingress protected devices, and data acquisition and prediction software. Major features of the system are as follows:

● Transforming physical mine into 3D virtual mine;

● On-line mine monitoring and prediction of hazards using IoT-based sensors and artificial intelligence (AI);

● Graphical representation of real-time sensor data, miners and asset tracking;

● Providing audio-visual warning and controlling of situation using IoT-enabled devices;

● Integrated data, voice and video communication;

● On-line production monitoring and resource management; etc.

�

|

|

|

|

|

|

Audio-visual warning device |

Sensor modules |

Miner�s tracking device |

Wireless communication device |

|

Digital mine system |

|||

National/International Status

The similar systems are available in foreign countries. However, the cost of the indigenously developed system is much lower than the similar imported one.

Patent/Technology Transfer/Commercialization details

● Patent: �Digital mine using Internet of Things�, Patent Filing Application No. 2020110292344, dated 10.07.2020.

● Copyright: �Digital Mine (DM) Software�, Copyright Registration No. SW-13978/2020, dated 10.12.2020

● Copyright: �Mine Environment Monitoring and Prediction (MEMP) Software�, Copyright Registration No. SW-13980, dated 10.12.2020.

● Technology Transfer: The technology has been transferred to: (i) M/s Knowledge Lens Pvt. Ltd., Bengaluru; (ii) M/s Coresonant Systems Private Limited, Secunderabad; and (iii) M/s Optimized Solutions Limited, Ahmedabad, for commercialization of the product.

Techno-economics

The system enhances safety and production in underground mines, tracks miners, facilitates wireless data, voice and video transmission from underground mine, provides 3D digital mine display with mining condition data and prediction of mine hazards in real-time, etc. These facilities make the system techno-economically feasible for installation in underground mines.

Societal Benefits

● More job opportunity to enhance production;

● Improved safety of mine workers; and

● Better environment in the mining areas.

Industrial Benefits

● Improvement is safety and production in underground mines;

● Tracking of miners with real time monitoring of location of men and machinery in the surface control room display;

● Ease in operation and rescue operation;

● Wireless data, voice and video transmission from underground mine;

● 3D digital mine display with mining condition data and prediction of mine hazards in real-time; etc.

Stakeholders/Clientele

Mining industries, electronics manufacturing industries, etc.

I-14 |

Road dust collecting and briquetting system |

In opencast mine, haul and transport roads are the major generating source of particulate matters. It contributes around 80% of total dust emission from an opencast mine. Therefore, if dust emission from mine roads is controlled, then the problem of air pollution in mining area will be reduced significantly. Generally, water is sprayed on mine road surface to control air pollution due to transportation. However, by this process air polluting source, i.e. dust is not removed from road surface. On the other hand, due to water spraying, road surface becomes muddy and slippery which creates difficulty for dumper operators while driving. Further, after a few hours water dries up and dust starts emitting again from road surface due to plying of vehicles. For effective control measures dust has to be collected from road surface and converted into solid form. A road dust collecting and briquetting system has been specially developed for collecting dust being accumulated on uneven mine roads and converting dust into solid form to reduce dust pollution in mining areas.

National/International Status

The integrated dust collection and briquetting system is not available nationally or internationally. Novelty of the system is as follows:

● It can be used on uneven mine roads;

● It can collect heavy amount of dust accumulated on mine roads;

● It can collect lumps which are less than 40 cm size/diameter; and

● It can be used as industrial vacuum cleaner.

|

|

|

|

View of field trials of road dust collecting system |

|

Field Implementation

Field trials of road dust collecting system were carried out in opencast coal and metal mines e.g., Jindal Saw Limited, Bhilwada and Rampura Agucha Open Pit Mine of Hindustan Zinc Limited, Rajasthan.

Patent/Technology Transfer/Commercialization details

● Patent: �Road dust collecting and briquetting systems for coal mines�, Patent No. 349337.

● Technology Transfer: The technology has been transferred to M/s Tata Motors Limited, Mumbai for commercialization of the product.

Techno-economics

The system is specially developed for collecting huge quantity of coal dust being accumulated on uneven road of mines and industrial areas. The system utilizes of waste coal dust as domestic fuel after converting into coal briquettes. These facilities make the system techno-economically feasible for installation in opencast mines.

Societal Benefits

The system controls air pollution in mining and industrial areas, which reduces health problem related to air born dust in mining and industrial areas. Significant number of employee will be engaged in manufacturing and operation of the system in mines and other industrial areas.

Industrial Benefits

● The system transform coal dust into coal briquettes for ready domestic use;

● The system reduces emission of air born dust consequently better air quality in mining and industrial areas, improves aesthetic of the surrounding leading to better human health;

● The system utilizes mine roads and stock pile coal dust which often acts as source of air pollution; etc.

Stakeholders/Clientele

Mining industries, thermal power plants, steel plants, cement plants, mechanical system manufacturing industries, etc.

I-15 |

Mine water reclamation technology |

A water treatment technology to reclaim coal mine water for drinking purpose has been developed by CSIR-CIMFR. Coal mine water normally comprises three major classes of contaminants, namely, suspended particulate matter, dissolved solids and microorganisms. The developed technology is able to address all three categories in a sequential manner. The process is based on the traditional water treatment practices of precipitation-coagulation-clarification-settling-filtration-ozonation. Suspended particulate matters are separated using appropriate polyelectrolyte flocculants, toxic dissolved matters such as heavy metal ions are removed using nanometric aqueous suspension and harmful microorganisms are addressed through ozonation.

|

|

|

|

Mine water discharge during mining |

Pilot Plant (4000 liter/hr capacity) |

|

|

|

|

Exterior view of Plant |

Ozone Generation Unit |

National/International Status

The analysis of available literature showed that by origin and by physical and chemical composition mine water is the closest to natural underground waters but from ecological point they should be regarded as a special type of industrial waste water. Mine water treatment method can be chosen on the basis of mine waters� chemical composition and climatic conditions of coalfields. One of the crucial problems of coal mines is the forming of acid drain waters, containing sulfate and metal. Currently, chemical methods are applied for their treatment. The cost of such treatment is high, while sulfates and metals removal efficacy is rather low. Microbiological treatment with sulfate-reducing bacteria, passive treatment with wetlands and calcite are alternatives to chemical methods. Currently, sorption treatment technology was also developed for mine water. However, each of those methods does not allow reaching the prescribed quality standards for the discharge of mine water into water bodies. Electrochemical method is effective for acidic metal containing water. In acidic mine drainage from Kizelovskiy coal basin was treated electrochemically in anode and cathode chambers placed in tandem with blade anodes and wire cathodes while treatment level from sulfates and metal cations was 80�100%. Thus, there is no universal method for mine water treatment due to diversity of their composition and a combination of technologies needs to be considered in order to achieve maximum environmental protection at affordable cost.

Field Implementation

After validation of developed technology through prototype coal mine water reclamation plant of 180 LPH capacity, a pilot scale plant of 4000 LPH has been designed and commissioned at Pootkee-Balihari mine site of Jharia coalfield. The plant is modular in nature and can take care of suspended particulate matter, dissolved heavy metals, hardness and microbiological contaminants. This plant can act as the piloting facility for any type of mine water with minor modifications. Ozone has been successfully used as the disinfecting agent in this plant. Probably, this was the first in India to convert mine water into drinking water and solving the problem of potable water availability in mining area. The mine water treatment plant was handed over to Bharat Coking Coal Limited (BCCL), Dhanbad after successful demonstration and imparting plant operation training to BCCL official to cater the drinking water need of the local people.

Techno-economics

The commissioned coalmine water reclamation plant at Pootkee mine site was designed to produce about 50,000 liter/day drinking water @4000 liter/hour. The commissioned coalmine water reclamation plant in its present capacity is able to cater the drinking water need of more than 6000 people if it runs for eight hours assuming the average drinking water need per person @5 liters/day. The water cost for this capacity has been worked out to be less than 20 paisa per liter. However, the cost will go down on increasing the plant capacity and a water cost of less than 5 paisa per liter may be achieved with optimum sizing.

Societal Benefits

Jharia, Raniganj and other Indian mining areas suffer with acute shortage of potable water in spite of the presence of large amount of unused mine water resources in these regions. Such shortfall can be compensated by utilizing available mine water resources in nearby areas after treatment and disinfection. This technology can also be implemented in coal washeries and other mining areas where mine water disposal and water availability is an issue.

The developed technology has the capability to convert waste mine water produced during the course of coal mining into drinking water. This is a translational research which will utilize a valuable resource, augment the drinking water resource for the local people and save the secondary contamination of surface water bodies.

I-16 |

KV-Lite CIMFR coal inhibitor |

Surface fire mainly in virgin coal bench, developed pillars, stock and overburden is very serious problem in coal mines. It is very difficult to control the fire (>300�C) using only water and top soil as surface sealing and surface mine fire temperature varies from site to site. In case of blazing fire (500-1000�C), no appropriate technology is available for control and combat of surface mine fire. Under these circumstances, chemical Inhibitor mixed with water will be very much suitable for direct application of surface fire for extraction of heat, suppression of flame and cooling of the strata (hot mass).

National/International Status

Literature review reveals the existing methods of application of water mixed with few chemicals sometimes are not reliable enough to prevent blazing fire. Flashing of water on red-hot coal fire debris can produces water gas, containing carbon monoxide and hydrogen gas, which are poisonous and highly explosive in nature. It is desirable that, the retardant should be in the capacity of increasing the cooling capacity of water, produce endothermic characteristics and reduce the occurrence of water gas explosion in case of use on high temperature coal fire.

|

LABORATORY TRIAL |

FIELD TRIAL |

|

Before firefighting operation |

Before Firefighting operation |

|

During Firefighting operation |

During Firefighting operation |

|

After firefighting operation |

After Firefighting operation |

Field Implementation

After carrying out internal demonstration in laboratory, field application was carried out in one blazing fire of surface coal mine i.e., New-Godhur-Kusunda Colliery of M/s Bharat Coking Coal Ltd., Dhanbad in January, 2017. Experiments were carried by spraying the mixtures of inhibitors along with water at a ratio of 1:100 on coal bench through water tanker of 18000 liters capacity. Flame and heat were reduced after 30 minutes and water spray continued for another 30 minutes on a surface area of 200m2 (10m x 20m) and temperature was cooled down to a range of 56 to 63�C from 642 - 668�C. The approximate production cost of the chemical is Rs.120-130/kg.

Patent/Technology Transfer/Commercialization details:

Patent filled No.: 0046NF2018 dated 23.05.2018

Societal Benefits

The controlling of surface coal mine fire eliminates both societal and environmental issues such as: declining air pollution, land degradation, global warming, damage to surface infrastructures through subsidence, desertification and economic losses.

Industrial Benefits

This will save natural resources and economic losses of the company and reduce constant hazard for the man and machines associated in mining operations.

Stakeholders/Clientele

M/s Coal India Limited; M/s SCCL, Kothagudam; M/s NLC, Nayvelli; M/s Tata Steel Limited, M/s NTPC

Future Plan

Better marketing and field demonstration in coal mines prone to spontaneous heating. Field demonstration at thermal power plants in coal stockpiles.

I-17 |

Contactless auto UV disinfection unit for touch screen, finger scanner and keypad of biometric identification and other devices |

After declaration of Covid-19 as global pandemic by WHO and suspension of use of biometric attendance devices, a new area of research was opened to provide solution. To inactivate the viruses from the surface of keypads, scanners, and touch screens of the biometric devices used by multiple users, a UV based technology was developed, which uses germicidal properties of UV-C radiations.

This technology provides solution for contactless and automatic sanitization of surfaces of biometric devices and makes them safe for use by multiple users. The advantage of the technology is that, there is no use of chemicals to disinfect the surfaces as well as it is contactless and automatic.

National/International Status

The developed product for biometric attendance can accommodate all sizes of BAS devices available in the market globally. All government offices, private industries and places of strategic importance nationally and internationally are potential users of the product. The technology was highlighted in the Compendium of CSIR Technologies for Covid-19 Mitigation published in January 2021.

|

|

|

Field Implementation

The technology is tested and certified by ICMR approved laboratory and is effective in inactivating 99% SARS-CoV-2 viruses in 1minute from the infected surfaces of biometric devices. The final product is ready for field implementation.

Patent/Technology Transfer/Commercialization details:

Patent: A patent application was submitted for developed technology. New Patent Application number 0100NF2020, dated 26.06.2020.

Technology Transfer/Commercialization: A technology transfer agreement was signed on 29/07/2020 for transfer of know-how and commercialization of the CSIR-CIMFR technology with an MSME registered firm, M/s Ashta Tech Automation Pvt. Ltd., Pune / Nagpur.

Techno-economics

The developed technology has good return on investment. As the technology is licensed to the technology partner a demand-based production is targeted in near future. The market value of the unit is driven by the demand, it is foreseen that, there will be a good demand in the market as much awareness about health, safety and hygiene is developed in the society during Covid-19 pandemic.

Societal Benefits

Biometric Attendance Systems (BAS) are used in all govt. organisatons as well as private industries/ offices to authenticate the presence of employees. In the present time of Covid-19 pandemic, sanitization of biometric based attendance systems (BAS) is important to ensure safe and virus free use of the BAS systems by the users.

The developed technology/product provides contactless and automatic and chemical free sanitisation of BAS systems before its use and can be important tool in government's mission for Swachh and Swasth Bharat Abhiyaan.

Future Plan

The developed and commercialized technology has number of applications and will play vital role in contactless, automatic and chemical free solutions for the devices which are used by multiple users.

I-18 |

Potassium fertilizer from biomass and spent wash ash |

Ash generated after combustion of biomass/ spent wash is a waste and the power plants are facing serious problems for its disposal. CSIR-CIMFR has developed the basic process for preparation of fertilizer from the ash. It is a zero waste and zero liquid discharge process. The process is being upscaled in collaboration with M/s EID Parry India Ltd., Chennai for pilot scale testing at their site and for subsequent commercial manufacturing in all of their distilleries. There are about 120 distilleries in the country with spent wash incineration ash and accordingly the potential for K fertilizer production is 0.2-0.3 million t/year.

|

|

|

|

|

|

||

|

|

||

|

Potassium extraction facility |

||

National/International Status

There are processes for extraction of potassium from different feedstocks like feldspar, mica, lignite, ash, slag, and the like. However all these processes involve complicated/tedious steps and machineries such as higher temperature, pressure, centrifugation, or leaching the mineral/ feed stock with chemicals and acids. The CSIR-CIMFR process is able to extract potassium from combustion wastes of biomass based power plants in simple eco-friendly steps under ambient conditions. Further, value addition to the extracted potassium is made so as to convert it into a slow release fertilizer using commonly available binders like gypsum, bentonite, montmorillonite, clay, molasses, starch, etc. The developed process does not involve any acid/ harmful chemicals, and sophisticated machineries.

Field Implementation

The process is being up-scaled in collaboration with M/s EID Parry (India) Limited, Chennai. A pilot plant is being installed at EID Parry�s distillery at Sivagangai District, Tamil Nadu.

Patent/Technology Transfer/Commercialization details

Patent App no. 201611041058. Agreement signed with M/s EID Parry for upscaling and subsequent commercial production.

Societal Benefits

Fertilizer is essential for plant growth and agricultural production. Balanced application of N, P, and K fertilizer is essential to sustain soil quality and crop productivity. In India, the fertilizer usage statistics shows that nitrogen [N] is used in a balanced manner through fertilizers and manures; phosphorus [P] is used excessively; but potassium [K] usage is deficient. Potassium imbalances are due to the lack of its local availability. The availability of organic K fertilizer at an affordable cost will help farmers to enhance organic farming. This technology will generate employment opportunities through collection, processing and transportation of biomass and other wastes.

Industrial Benefits

In India there are many biomass based power plants and about 120 distilleries with spent wash incineration ash. The disposal of the ash is a big challenge. This technology offers a solution for sustainable use of ash and additional income to the power plant/distillery.

Stakeholders/Clientele

M/s EID Parry (India) Limited, Chennai

Future Plan

After successful pilot scale demonstration at industrial site, the technology will be implemented in the distilleries and biomass power plants using their respective waste ash.

I-19 |

Technology of recycling waste lubricant oil in a commercial low cost ANFO explosives for mining applications |

Disposal of used lubricant oil in an ecosystem is a serious environmental threat. In this context, recycling of waste lubricant oil into a valuable product has an immense commercial and environmental significance and is a challenging area of research. CSIR-CIMFR has developed a technology of recycling waste lubricant oil in commercial low cost ANFO explosives for mining applications. Moreover, the effect on detonation properties and rock fragmentation patterns by the use of lubricant oil based ANFO in blasting operation has also been studied. Field trial experiments were carried out with lubricant oil based ANFO explosive to demonstrate the real applicability of the prepared explosive composition at Nimbeti Limestone mine of Shree Cement Limited, India. These explosive compositions revealed effective detonation performance. Importantly, air quality were analyzed during blasting operations indicated that the emitted toxic fumes such as CO, NOx and fine dust particles (PM2.5 & PM10) were found to be within the permissible limit at the mining area by the use of lubricant oil based explosives. Further, rock fragmentation analysis indicated that ANFO explosive compositions with 20%, 30% and 40% (w/w) lubricant oil in diesel oil revealed good rock fragmentation as compared with normal ANFO in the conducted experimental blast.

National/International Status

Efforts have been made in the last few decades for the various alternative fuel phases of ANFO such as coal dust, confectioners� sugar, aluminium powder, TNT, sugar cane bagasse, rice straw, corn cob, tyre residues and biodiesel by various research groups. Apart from bio-diesel, the other alternative fuels showed poor detonation properties compared to ANFO. Importantly, effective consumption of hazardous materials like waste lubricant oil in the form of useful explosive product is highly desirable from commercial and environmental point of view. Only few examples were reported where used lubricant oil was recycled in manufacturing of commercial explosives. These works described safety operation conditions of lubricant oil in explosives at low temperature. However, the effect of lubricant oil in fuel phase on detonation properties of ANFO, blast performance and its environmental impact analysis were rare in contemporary literature. In India effective use of lubricant oil in ANFO is rare in the explosive industry.

CSIR-CIMFR technology provides an example of an effective field demonstration of lubricant oil based ANFO explosive with significant detonation properties and with minimal environmental hazardous impact in and around the mining site.

Field Implementation

An extensive field study was conducted at Nimbeti limestone mines, Rajasthan. ANFRO explosive compositions were prepared at the field using the processed use oil, diesel oil and prilled ammonium nitrate. Further, rock fragmentation analysis indicated that ANFO explosive compositions with 20%, 30%, and 40% (w/w) lubricant oil in diesel oil revealed good rock fragmentation as compared with normal ANFO in the conducted experimental blast. Importantly, air quality was analysed during blasting operations to indicate that the emitted toxic fumes such as CO, NOx, and fine dust particles (PM2.5 & PM10) were found within the permissible limit at the mining area by the use of lubricant oil based explosives.

Prepared ANFRO explosives

Patent/Technology Transfer/Commercialization details

Indian Patent filed vide Application No. 202111014942 date 31.03.2021

Techno-economics

This technology will reduce the cost of the explosives and will provide a cheap and effective approach of rock blasting with emission of less toxic gases to the environment. Industry as well as society will be highly benefited by this technology.

Societal Benefits

Used lubricant oil is considered as a hazardous waste associated with environmental pollution. Disposal of lubricant oil is an environmental burden and its eco-friendly disposal is a matter of concern. CSIR-CIMFR technology will provide an easy way of recycling a hazardous waste material to a useful low cost commercial explosive product. The society will be highly benefited by the use of this developed technology.

Industrial Benefits

Mining industry will be highly benefited by this technology. This technology will provide an easy way of recycling the waste material to a useful low cost explosive product. This product will reduce the cost of the explosive by almost 50%.

Stakeholders/Clientele

M/s Smartchem Technologies, Pune

Twitter

Youtube

Facebook

Contact us