|

I-20 |

Technology for dust control during blasting operations |

Dust generation during blasting operations impose serious environmental, health and Dust generation during blasting operations imposes serious environmental, health and operational hazards in and around the mining area and is a big threat towards sustainable eco-friendly mining operations. CSIR-CIMFR has developed a technology by formulating suitable dust suppressant chemical compositions for the reduction of dust emissions during blasting operations.

National/International Status

Significant efforts have been made by researchers to control the dust generated during blasting operations in the last few decades. Bhandari et. al described various control methods to control the dust generation during drilling, transportations, etc. at the mining site. T. N. Singh introduced an approach of dust generation control with the control of blast design parameters. Joao R. Talamoni invented the dust suppressant composition comprising an aqueous solution of polyvinyl alcohol, acrylic-based latex, glycerin, silicon-based surfactant and poly silicoxane based wetting agent. The composition is applied over the dusting materials preferably spaying over the material and dried at room temperature. This composition is not suitable to reduce the dust generated by blasting operations. Further, Ko et al. introduced a water tube with a detonating cord for the effective control of dust during the demolition of buildings or structures. However, all the previously discussed methodology has some limitations and is not effective enough for commercial applications. CSIR-CIMFR dust suppressant technology is a unique example where the developed composition is capable of controlling the dust during the rock blasting operation.

Field Implementation

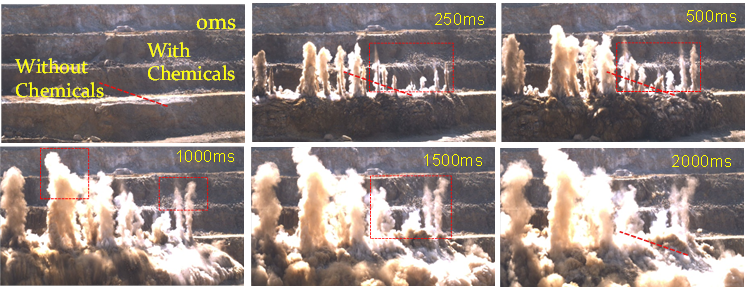

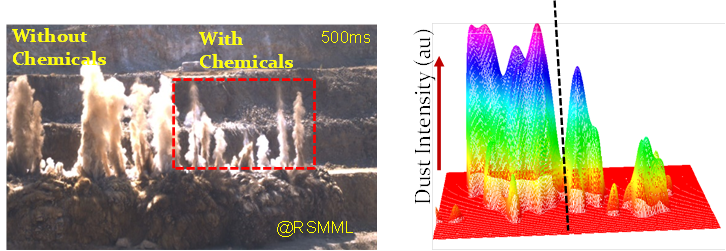

Three field experiments have been conducted at the mines with the CSIR-CIMFR developed technology. In the trial blasts, half of the blasting hole was treated with prepared chemicals and the remaining half was treated as a control to compare the efficiency of the dust suppression during blasting operations. The blast-induced dust emission was captured using high-speed video and data was analyzed using the software. Results indicate that more than 45% of dust emission was suppressed with the use of the prepared chemical composition in comparison with the normal blast conducted without chemicals. Importantly this technology will help us to control the dust generated during the blasting operations for eco-friendly mining.��

Patent/Technology Transfer/Commercialization details

Patent filed vide Application no. 02011000277 dated 03.01.2020.

Effect of prepared chemicals to suppress the dust generated during blast operations and 3D representation of the analyzed data.

Techno-economics

This technology will effectively reduce the dust pollution in and around the mining area, which eventually enhances the productivity of the mines and the safety of the miners.

Societal Benefits

Considering the needs of the mineral of our modern society, there is an urgency to look for an advanced technique for sustainable green mining. Huge emissions of dust will be controlled in the mining area by the use of this developed technology. This technology is one step forward towards sustainable green mining.

Industrial Benefits

The mining industry will be highly benefited by this technology. A dust-free working environment will enhance the productivity of the mines and reduce the time scale.

Stakeholders/Clientele

M/s Tata Steel Limited

I-21 |

Intrinsically safe real-time environmental monitoring system for underground coal mine |

|

|

|

Intrinsically safe real-time environmental monitoring system |

An intrinsically safe real-time environmental monitoring system has been developed for continuous monitoring of various parameters, namely methane, carbon monoxide, oxygen, air velocity, temperature, machine status, etc. at a plurality of locations even in gaseous underground coal mines. The system also gives audio-visual warnings when particular parameters crosses the threshold value and switch off the power supply of a particular section of underground coal mine in case of occurrence of high methane concentration.

Field Implementation

The system has been successfully operating in 10 mines of SCCL, ECL, BCCL, IISCO, TISCO, etc.

Patent/Technology Transfer/Commercialization details :

● �Multi-channel intrinsically safe real time environmental monitoring system for underground mines�, Patent No. 259777.

● Technology Transfer: The patented technology has been transferred to M/s Jagadamda Tyre Retreading Company, Dhanbad for commercialization of the system.

Techno-economics

The development of low cost indigenous environmental monitoring system has increased safety of underground coal mines and enhanced the import substitution of similar equipment.

Industrial Benefits

● The system helps in detecting the slow deterioration in the ventilation system/environmental condition and detects heating or increase in methane or carbon monoxide concentration much before an occurrence of an accident or catastrophe.

● The system switches off the power supply in case of occurrence of high methane gas concentration beyond the limit to prevent explosion in a particular working area.

● Enhanced safety for underground mine workers

Stakeholders/Clientele

Mining industries, electronics manufacturing industries, etc.

Twitter

Youtube

Facebook

Contact us